From Garage Builds to Industry Giants: The Story Of ADF & How They Became The Gold Standard For Subaru Lift Kits

By Ben Boxer

If you’ve been in the lifted Subaru game for any amount of time, there’s a good chance you’ve heard of ADF (Anderson Design & Fabrication). And if you haven’t, get in and buckle up nerds, because the story of how Patrick turned some scrap steel and a college basement shop into one of the most respected off-road Subaru brands in the country is legendary.

I sat down with Patrick at his 5,000 sq ft warehouse to pick his brain about everything from the humble beginnings of ADF and their current product offerings, all the way to applicable knowledge for those who are currently building their Subaru.

Feel free to watch our entire conversation here:

Humble Beginnings (a.k.a. The Basement Builds)

Patrick didn’t set out to start a company. Like most of us, he was just trying to make something work. Living on ramen, commuting to Portland State University in a tired old Subaru, and armed with an engineering brain and a stubborn streak, he welded up his first lift kit in the basement of Shattuck Hall. It was ugly. It was heavy. And it worked.

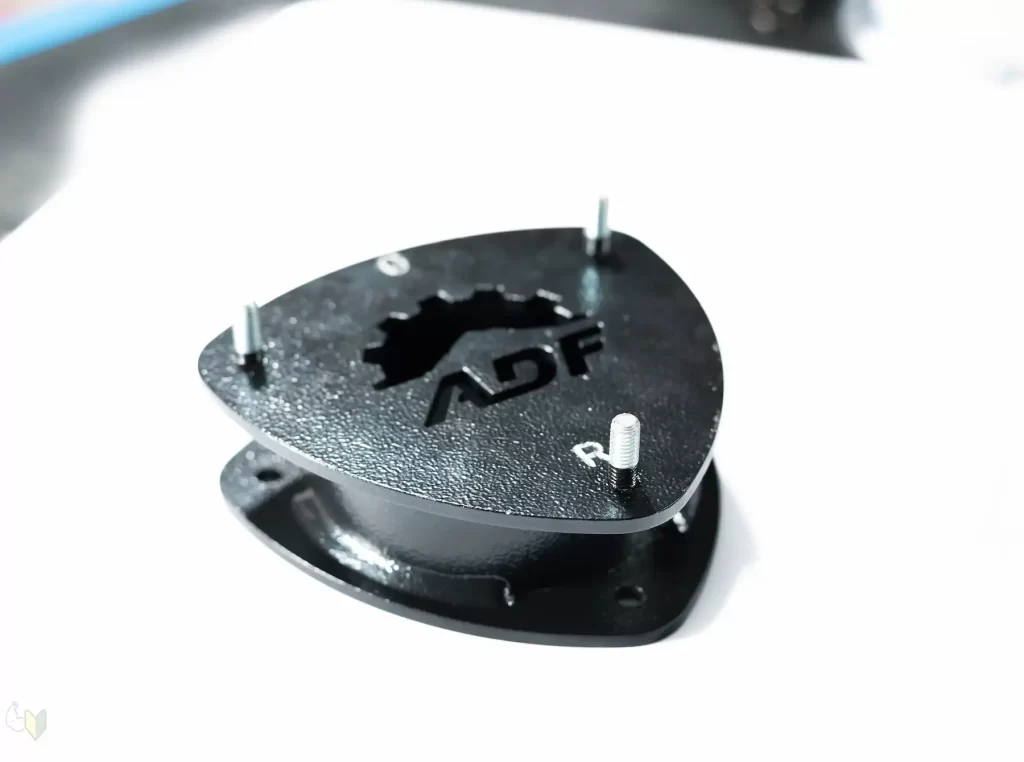

“The first lift kit I built was in the basement of Shattuck Hall at Portland State… square tube, drilled some holes, cut ’em out at an angle — whole nine yards.”

That first “ghetto lift” kit sold for sixty bucks but that spark led to a few more builds. Then a few more. And before long, through nothing more than word of mouth, the side hustle that initially just helped pay rent started taking over. The money he was earning making lifts on the weekend started to eclipse the salary he was earning at his regular career. He eventually chose to leave his job with the city and pursue fabrication full-time.

From College Commuter to CNC

ADF was never backed by a trust fund or flashy investors. In fact, upon meeting each other and talking about our upbringings, Patrick and I realized that we both went to the same food pantry with our parents over 25 years ago just to get by. ADF grew the old-fashioned way: sweat equity, trial and error, and a relentless pursuit of being better.

Patrick was working jobs with the city, welding lift kits at night, and selling them through Facebook groups and Instagram DMs. No website. No marketing budget. Just quality parts and word of mouth.

“I sold three lift kits, then made six more. That was the cycle. It just snowballed…I didn’t even have a website at the time. Just Instagram and a few Subaru Facebook groups.”

I first purchased a set of Outback trailing arm spacers in 2013 or 2014. I had no idea at the time that they were still a tiny startup that was in its infancy at the time. Little did I know that they were only going to explode in popularity and authority in the Subaru offroad community.

Building a Brand Through Grit

Today, ADF is synonymous with top-tier Subaru lift kits. But that didn’t happen by accident. Patrick built the business on three principles: quality, customer service, and constant iteration. If it can be improved, he’s going to tweak it. If a customer has a problem, he’s going to fix it. And if a part breaks? He’s going to build it stronger.

“Failure was the biggest part of building this business. We’ve scrapped more parts than I can count. You learn fast when you mess up a whole batch of 300 spacers and realize they’re unusable.We’re constantly tweaking things. There’s always a better way to build something.”

And that philosophy has paid off. With customers across the world and products that consistently outperform the competition, ADF has become the go-to name in a niche that used to be little more than DIY forum posts and rusty Forester strut swaps.

More Than Just A Lift Kit Manufacturer

ADF doesn’t just lift Subarus. They build out the full experience. Skid plates, molle panels, fender braces, sway bar extensions – all designed with obsessive attention to detail. Every part gets prototyped, scanned, stress-tested, and fine-tuned. Patrick doesn’t launch parts because they’ll sell. He builds what he’d run on his own rig.

“Any time we run into a bottleneck, we sit down and figure out how to get rid of it. That’s what led to the robotic welder and the laser cutter. ”

That commitment to innovation is backed by serious investment. Patrick has poured capital into top-tier equipment – robotic welders, CNC press brakes, and industrial-grade laser cutters, not just to produce his own line of parts faster and better, but to help other brands, too. ADF now supports small and mid-sized fabricators by producing private-label parts with the same quality standards they apply to their own.

“We dropped cash on a 4-kilowatt Mitsubishi laser that can cut one-inch steel. We’re all about innovation and quality. In fact, A lot of smaller companies come to us for production. We produce private-label parts with the same tolerances and weld quality that we put on our own gear.”

And the gear gets used. Hard. We’re talking people sending Subarus into rocks, trees, and through the kinds of trails that make Jeep guys do a double-take. The fact that Patrick can take feedback from that abuse and use it to make even better products: that’s what sets ADF apart.

Innovation Backed by Guts (and a Lot of Steel)

When COVID hit and the industry was slowing down, ADF doubled down. Instead of waiting months for outsourced parts, Patrick bought a laser cutter and press brake. Then came the robotic welder. No investors. No debt spiral. Just guts, spreadsheets, and a drive to keep making everything in-house.

“We prefer to pay cash for almost everything. That slowed our growth, but it kept us lean and in control.

I remember watching ADF’s growth in popularity during the pandemic. I think his willingness to take the leap of faith into purchasing millions of dollars worth of manufacturing equipment was a huge factor in this. While everyone else was months out on lift kits and offering less than perfect parts, Patrick and his team were in full operation and not only delivering great quality control, but constantly improving.

Why ADF Stands Out Among The Other Subaru Lift Kits Manufacturers

In a space that’s getting crowded fast, ADF keeps rising. Here’s why:

Experience: Patrick’s been building for over a decade. His parts work because he’s tested them and understands the difference between modding 4×4’s and Subarus for offroading.

Engineering: Offset camber-correcting spacers? Reinforced skid plates? Welds like a spaceship? All intentional. And not to mention the high standards Patrick holds for using only the best materials. You won’t find cheap hardware, low grade steel, or crappy paint on their parts.

Customer support: You break something? You get a real answer, probably from the guy who designed and built it.

What's Next For ADF?

ADF isn’t just here to sling parts. It’s a large part of a movement in the Subaru community. The off-road Subaru scene has exploded in recent years, and guys like Patrick are the reason we can take our Subies places they were never “supposed” to go.

So next time you see a lifted Outback bombing down a decommissioned logging road or a Forester flexing on some rocks, there’s a good chance it’s built with ADF parts.

You can stay up to date on all of their innovation by visiting their site or following them on social media @anderson_design_fabrication to get an inside look on their day to day operations.